With energy prices skyrocketing, the climate under threat and legislation evolving to keep up, commercial kitchen operators should be switching on to the importance of maximizing energy efficiency. By saving energy and making the most of every watt, operators can cut their costs as well as minimizing their carbon footprint.

Image: AdobeStock | Goinyk

“50 years ago, fuel or gas prices may have been minor compared to labor or food costs, but today, the ratio of energy costs is dramatically higher,” says Stephan Leuschner, director of ghost kitchens, culinary concepts & broadcast at Rational and host of the popular TrendTalk live webinars, which focus on ghost kitchens and the food delivery market.

According to Mudie et al in the International Journal of Low-Carbon Technologies, between 45 % and 70 % of electrical energy is wasted in a commercial kitchen through shortcomings like insufficient training and poor equipment maintenance. The good news is that energy transformation is possible, and here are six ways to stop energy waste in your professional kitchen.

-

Know your power

The first step towards greater energy efficiency is an energy audit. This will reveal the areas of greatest energy consumption and can be compared to similar establishments to help set new targets. Smart technology , e.g. ConnectedCooking, can provide real-time information on resource usage. Deep dive into your energy provider to ensure you are on the right business tariff and consider providers that use renewable energy sources. Increasingly, electrical energy is being favored over gas in foodservice.

-

Choose the right equipment

One of the main contributors to energy consumption is a professional kitchen’s equipment. In Mudie et al’s study, refrigeration accounted for 41 % of energy consumption, fryers 13 % and combination ovens and grills 12 % each.

Technological developments are enabling ever more efficient equipment in almost every area of the kitchen. “There have been vast improvements in equipment in the last five years,” says foodservice consultant William Bender FCSI, founder and principal at W.H. Bender & Associates. “It can save money in the operation and improve quality at the same time.”

Modern deep-fryers are more energy efficient and also help save fryer oil by reducing scorching. According to UK catering equipment provider Die-Pat, a connectionless steamer can reduce water use to two gallons per hour from 40 gallons per hour, as well as reducing heat loss. Grills with infra-red elements enable up to 80 % more efficient heat transfer and can be designed to switch themselves on only when a product is placed under the heat source. A combi-oven reduces cooking time and improves air circulation, while microwave ovens use up to 90 % less energy than conventional ovens.

Image: RATIONAL

When buying equipment, look out for EU energy labels or Energy Star ratings. More efficient equipment may be more expensive in the short run, but they usually pay for themselves over time, with the added benefit of helping to protect the planet.

-

Maintain your tools

Once you have the right equipment for the job, it is vital to maintain it properly. The condenser coils of a refrigerator can become coated with dust, which acts as an insulator and impairs their ability to remove heat. Calcification and mineral deposits in water filtration systems undermine their efficiency. Dirty ovens waste energy, as they are less efficient and additionally present a safety risk.

A robust maintenance schedule is an essential part of optimizing equipment performance. Any leaks or breaks should be addressed at once to avoid wasted resources. Business Energy estimates that an annual service of the kitchen’s heating system can improve overall energy efficiency by up to 15 %.

-

Leverage smart design

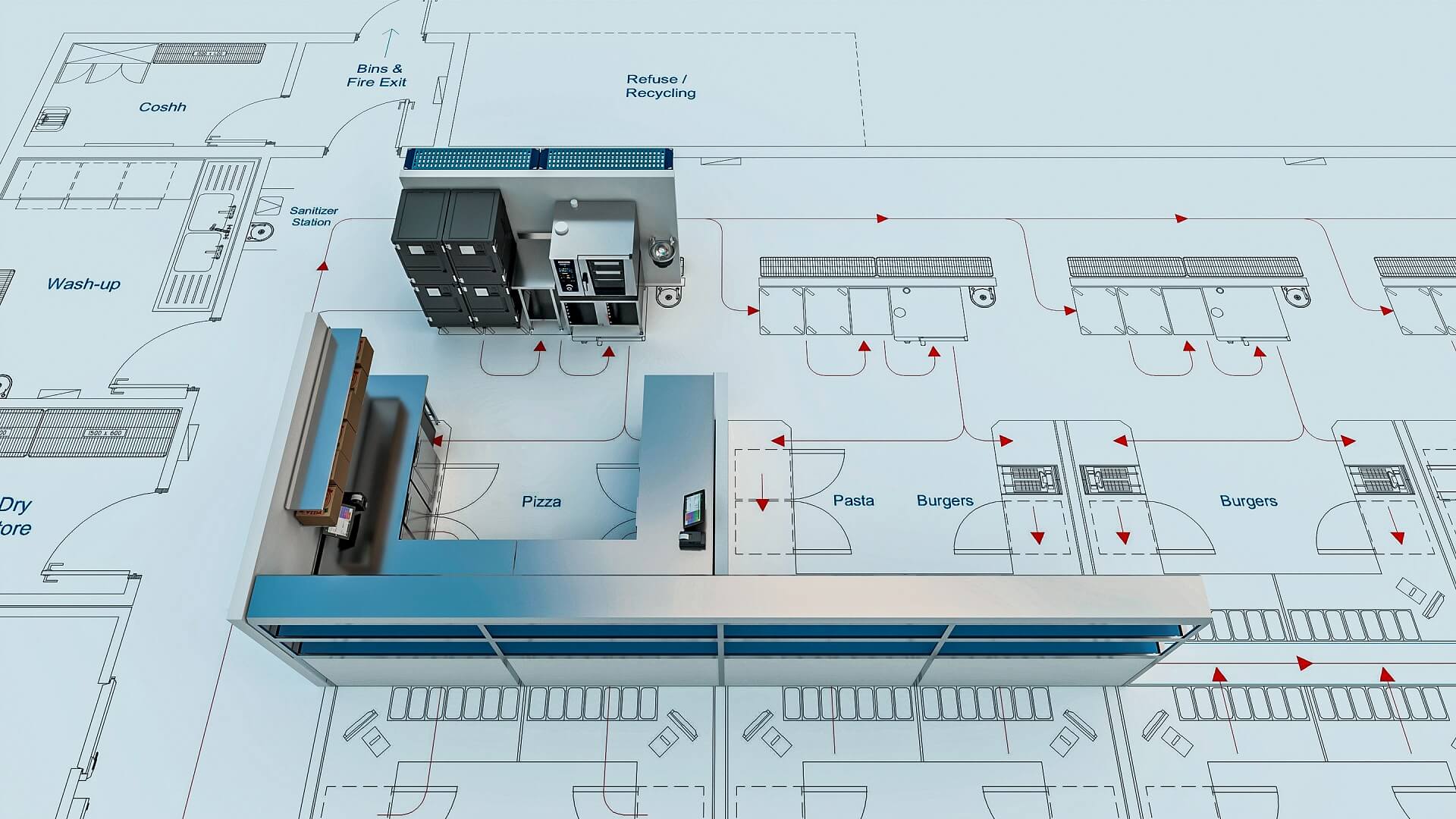

Kitchen layout, orientation and airflow management are some of the overlooked champions for overall efficiency. For example, if your refrigerator is located next to the cookers, it will have to work much harder. By defining separate zones for heating and cooling equipment within the kitchen, operators can reduce the strain on their equipment, reducing energy consumption and the chances of failure.

Image: RATIONAL Webinar

Poor kitchen airflow can put extra strain on HVAC equipment and vents. Defining HVAC zones, upgrading airflow and following manufacturer guidelines for ventilation space around equipment can improve overall performance.

“Many kitchens are planned in a traditional way, meaning you over-dimension,” adds Leuschner. “Having a small footprint with less people and more efficient work saves energy and cost. When you are planning a kitchen, you should consider what you really need.”

-

Know when to switch off

“The easiest way to change consumption is to optimize the operation,” says Leuschner. “The more cleverly we plan our operational workflow, the higher the efficiency. This means creating an optimized start-up/shutdown schedule to capitalize on peak times and avoid wasting energy for equipment that isn’t in use.”

For example, lights should be switched off when not being used, and fryers can be turned off during quiet periods. Smart technologies can be used to do this automatically.

Image: RATIONAL| Sapori

-

Shape your culture

One of the main areas of improvement identified by Mudie et al is staff behavior. “When you’re talking about reducing emissions, stopping energy waste or saving money, it really depends on the culture,” says Bender.

Training and signage can be used to help staff members make efficient choices. Procedures such as ensuring that dishwashers are full before being switched on, closing fridge and freezer doors and turning off equipment should be routine and can be defined in the employee handbook in order to stop energy waste efficiently.

Customers can be brought along on the energy efficiency journey too. Consider designing the menu to take into account cooking methods and make the most of dishes that can be cooked fresh, rather than relying on pre-cooking and cooling or buffet-style service.